AbstractThe science of today is the technology of tomorrow.

Edward Teller (1908–2003)

Theoretical physicist

In recent years, frugal innovations have become widely popular due to their no-frills nature that entails lower costs. However, most of the frugal innovations, at least at the grassroots level, are makeshift contraptions, made from indigenous ingenuity, that achieve their goals under constraints on various resources but may suffer from limited lifespans due to premature failure. Consequently, it is imperative that sound scientific principles not be overlooked or haphazardly applied in realizing these innovations, irrespective of their grassroots or sophisticated nature. This article therefore argues for the need to use science, sometimes at the cutting edge, to realize grassroots and advanced frugal innovations that are not prone to failure under various working conditions. In so doing, this work advocates the use of classical and new design methodologies that are rooted in science to save resources and, hence lower costs, while aiming for robust functionality of frugal products. In particular, a frugal design approach using a modern version of the safety factor called the “factor of frugality” has been propounded to effectively create any type of frugal innovation from scratch. By combining the ingenuity of the resourceful creators of frugal innovations with a scientific approach that aims to make the resulting products “fail proof”, such innovations may better contribute value to business and benefits to society.

Introduction

The notion of frugal innovation, with its conceptual origins arising from observations of grassroots-level innovation (Basu, 2007; Raturi, 2010), mainly in India and China, has captured the attention of researchers and practitioners in developed countries (The Economist, 2010). Frugality has been associated with engineering and innovations and has been touted as a significant tool for creating low-cost products and services in an era beset by crises including planetary ones such as climate change and resource scarcity (Rao, 2013). Frugal products are also catering to the needs of both the poor and lower income segments, whose ranks are swelling in developed and developing nations alike due to man-made crises such as the bursting of the dotcom bubble and the global financial calamity of 2007–2008.

Although the concept of “frugal innovation” took root in the inventiveness of very talented grassroots creators of emerging economies, numerous products and services in sectors ranging from education and healthcare to applications in space have been realized with an eye for lowering costs through a “no frills” structure (Rao, 2013). Examples include the production of low-cost products such as the Tata Nano car and Tata Swach filters for potable water by the Indian conglomerate Tata Sons. Another example is the no frills refrigerator called chotuKool by yet another Indian business, Godrej & Boyce. Other than products showcased by Indian business titans, other countries are also jumping onto the frugal bandwagon as is evidenced by handheld electrocardiograms and portable ultrasound scanners developed by General Electric of the United States and also the Square Kilometre Array in South Africa (Nordling, 2012), built from nonoperational communications antennas retrofitted into a radio telescope for peering into space. Frugality has also been observed in other recent high-tech products, such as the robotic hand from Sandia Labs (Greenemeier, 2012); a salt telescope in Africa (Nordling, 2013); the small Spike missile developed for the US Navy (The Economist, 2012), and a low-cost technology for particle colliders in high-energy physics applications (Downer & Zgadzaj, 2014; Rao, 2017a). In services, the appearance of no-frills flights by low-cost airlines (The Economist, 2014) and complex heart surgeries offered at lower prices by Narayana Hrudayalaya in Bangalore, India (Khanna et al., 2005) are prominent examples.

Moreover, as observed in the examples covered above, frugal innovations encompass both grassroots and sophisticated types, with the latter being termed as advanced frugal innovations (Rao, 2017a). In other words, an advanced frugal innovation is systematically created through rigorous application of scientific methods, whereas its grassroots brethren are typically makeshift contraptions that are realized through very talented innovators possessing significant ingenuity. Also, an advanced frugal innovation is developed against an imposed constraint on resources whereas the grassroots type are developed by the poor against natural constraints. But, cases of advanced frugal innovation are not rare exceptions. Other than the 25 examples of frugal innovation recently examined by this author (Rao , 2017a), the majority of examples qualify as advanced frugal innovations due to the degree of sophistication in science and technology needed for their systematic realization (see, for example: Rao, 2013).

The advanced frugal innovations developed to date are a testimony to the knowledge and also ingenuity of the creators (i.e., engineers, scientists, and other workers) in their endeavours for cutting costs while attending to the stringent needs of science, engineering, and other relevant knowledge areas. Although frugality lends itself to sustainable solutions for tackling the crises of our times, the act of indulging in these innovations has to be tempered with detailed knowledge. In other words, frugal innovations have to be firmly supported on the sound principles of science and engineering. Such an association would not only enhance the potential of these innovations in critical sectors such as healthcare and aviation but would also encourage the private sector and other entities to increase the market share for commercial products built on the concept of frugality.

Therefore, this effort will focus on deepening the association between frugal innovations and science and hence make the frugal concept more than a makeshift arrangement. Weaving science around these innovations would make them amenable to the myriads of approaches available in engineering literature for the systematic realization of these innovations into quality products. The term “science” as used in this effort comprises both basic and applied science or engineering. In particular, some relevant existing engineering methodologies will be examined that will consequently lead to the need for a “factor of frugality” in making frugal innovations of superior quality. A scientific framework based on the factor of frugality approach will also be presented for the systematic realization of these products whose functioning is not hampered by frugality. Moreover, for frugal innovations of the grassroots type, any attempt at strengthening their foundations through science – using tools such as the factor of frugality – would enhance their usefulness at the base of the pyramid wherein exists a significant stakeholder for sustainable development.

Performance of Frugal Innovations

The premise underlying the concept of frugal innovation is the achievement of lower costs against natural constraints for the grassroots type and resource-savings through artificial constraints for the advanced type. In either case, a no-frills structure is achieved through various aspects aiding in the real-time realization of these innovations. These aspects cover design, materials, and manufacturing, and supply-chain logistics, to name a few. However, the design, materials, and manufacturing aspects of these innovations are by far the most significant due to their direct bearing on the quality performance of a frugal product in the real world. In other words, engineering leads to the realization of frugal products and any compromise in the rigours of its tools (i.e., design, materials, and manufacturing) would hamper the effective functioning of the product concerned. Such a sacrifice in rigour while designing and building a product for achieving a no-frills structure is a real possibility for grassroots innovations due to their makeshift nature. Moreover, the zero scores achieved in recent crash tests of some of the relatively cheaper cars for the masses (Global NCAP, 2014) and the glitches in both the salt telescope in Africa (Nordling, 2013) and the radio telescopes of the Square Kilometre Array project (Nordling, 2012) imply that there may be less rigorous engineering for advanced frugal innovations when working under a bootstrapped budget. Furthermore, multiple design iterations might be warranted even after adopting a rigorous design process to iron out all the weak spots of a frugal product as is evidenced by the reported malfunctioning in the first generation Tata Nano car (The Economic Times, 2010; The Economist, 2011), which has been rectified in the latest version. In other words, the Tata Nano has gone through at least two iterations of design to arrive at the latest model, and this attests to the complexity of rigorously designing this and other advanced frugal products, which makes the ironing out of weak spots difficult in the first instance. The successful development of the Nano through these design iterations was ultimately made possible through the rigorous application of scientific principles by an ingenious workforce possessing advanced skills. Indeed, these examples of advanced frugal innovations again attest to the ingenuity and the knowledge-based skills of the workforce involved, some of whom are continuously improving the quality of their products. Although less rigour in engineering practices could be tolerated in grassroots innovations such as earthen refrigerators (Raturi, 2010) and bamboo microscopes (Basu, 2007), stringent engineering practices should be the norm for advanced frugal innovations used in sectors such as the healthcare and aerospace industries, where human lives are at stake. Thus, engineering rigour should be made compulsory or the norm for any frugal innovation achieved through the ingenuity of innovators, whether the products are of the grassroots, advanced, or any other type.

It should be noted that the theme of frugality has been applied to both products and services. However, even though this effort focuses on the improvement of frugal products, the same theme of rigorous procedures for achieving good quality is also applicable for improving the quality of frugal services in areas such as healthcare, where the need for speed to achieve economies of scale in surgeries is of concern (Nagral, 2014).

Scientific Framework for Frugal Innovations

The weaknesses imposed on these innovations, by their very aim of achieving frugality, could be minimized or even avoided by applying suitable engineering design tools rooted in scientific principles. Therefore, the design and engineering of any frugal innovation, whether grassroots or advanced, must be subjected to scientific rigour to harness their true potential for sustainable development. The scientific framework based on engineering design measures that are advocated in this study applies to both the grassroots and advanced frugal innovations. Therefore, both the collider for particle physics (Downer & Zgadzaj, 2014, Rao, 2017a) and the earthen refrigerator or MittiCool Fridge (Rao, 2013) need the ingenuity of their creators in using such a engineering framework to realize these game-changing innovations with the collider also needing advances in other relevant knowledge areas, such as particle physics, for its completion.

The approach outlined in this study brings out the necessity of using sound engineering principles for improving the quality, and hence usefulness, of frugal innovations. As mentioned before, the design and manufacturing of a frugal product from scratch is assumed to be the primary approach for achieving frugality with the utilization of other features, such as supply chain and quality-control tests, being secondary or ancillary. Consequently, this effort emphasizes the usage of the classical factor of safety and hence its extension the factor of frugality due to the ubiquity and also the inter-relationship between design measures and the factor of safety. Accordingly, some of the relevant design principles based on the factor of safety have been expounded to undergird the factor of frugality approach to design and engineering.

Factor of safety approach

The frugality of an innovative design will usually push the traditional factor of safety or safety factor (FOS) (Shigley & Mischke, 1989) towards a numeric value of one. Since a unit value of the FOS corresponds to the failure-prone load being equal to the working load, many frugal innovations could possibly be experiencing maximum loads with a propensity to fail due to poor design. In other words, frugal innovations may routinely be pushed to their limits under normal working conditions. The predominant reason being that no-frills designs of frugal innovations are typically realized with minimal amounts of raw materials that in turn lower their factor of safety. Other reasons for an unsafe design include uncertainties in the models and data needed for the design, which in the case of grassroots innovations might not be accessible in the first place due to the absence of a suitable knowledge base.

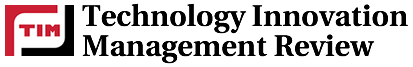

Accordingly, a preliminary scientific framework for realizing frugal innovations of both the grassroots and advanced types with robust functionality is depicted in Figure 1. The framework depicts the classical approach to design that has traditionally been followed for creating engineering structures and products (Shigley & Mischke, 1989; Urugal, 2015). The various elements of the framework depicted in Figure 1 represent a knowledge base that is widely used by designers and engineers around the world. A rigorous design procedure reducing uncertainties through accurate models for design, engineering, and scientific phenomena; precise selection of materials and manufacturing processes limiting waste; and accurate prediction of scenarios for overloading, to name a few, would also lead to FOS values in the vicinity of one but with a reduced susceptibility to failure. The conceptual stage would also involve multiple iterations of the rigorous design process, where needed, to iron out as many bottlenecks as possible in the modelling, material behaviour, sustainable manufacturing, overloading, and other aspects of design during this initial stage because design modifications would be difficult to implement during fabrication. The various principles, shown in Figure 1, facilitating a rigorous design procedure accompanying a lower factor of safety, are described in the lines that follow. These principles form the bedrock of a rigorous frugal-design and will be adhered to in the factor of frugality approach, described later, for the systematic realization of robust frugal products:

- Accurate design and engineering models: After conceptualization, the mathematical models used to capture the complex features of the functioning of a product are important to its design and subsequent engineering. These models have to encompass the important features of a product while being tractable for accurate solutions. The term “accurate” signifies the error with respect to the exact solution or real behaviour that can be tolerated. While working with frugal designs, it is imperative that tight tolerances are strictly implemented for error due to the low FOS values inherent in the design of these innovations. In other words, model predictions ideally have to match real values so as to avoid failure whose chances are high due to lower safety factors. But realistic conditions introduce a risk of error that has to be maintained at such low values that the chance of failure becomes insignificant. Since the progress in both technology and knowledge base, such as science, engineering, or any other relevant area, will dictate the limit on accuracy, it is imperative to seek accurate models through research & development (R&D) programs dedicated to frugal products. These R&D activities should also strive to obtain exact values or real-time behaviour through meticulous experimentation or real-time tests so as to reduce their margins of uncertainty for effective comparison with model predictions.

- Accurate characterization of material behaviour: The lower values of FOS also necessitate accurate characterization of the behaviour of materials going into a frugal product. The various properties critical to the design of a frugal product have to be procured through well-controlled experimental tests generally yielding data with least uncertainty and also good repeatability. This is because frugal products are typically designed without excess material padding and hence require accurate estimation of material properties to lead to a product that is lean and also robust and effective in its performance. Therefore, improved accuracy in outputs of both mathematical models and material characterization would aid in minimizing design uncertainties, which is critical considering the inherently higher stresses experienced by frugal products. Moreover, these accurate models in engineering and materials should also be utilized to widen the range of size, shape, and type of parts for standardization so as to lower costs for fabrication and assembly.

- Sustainable manufacturing: The need for economy in the usage of materials for building a frugal product beckons the use of manufacturing technologies that minimize generation of waste. In this regard, sustainable manufacturing processes, with their emphasis on lower emissions and also lower waste, should be utilized to fabricate products out of frugal material resources. An instance of technology for sustainable manufacturing would be the use of near-net shape-manufacturing processes, such as additive manufacturing or 3D printing, for building frugal products with the attendant meagre waste.

- Low probability events: The low FOS design of a frugal product should envisage and also account for scenarios of rare events where the product might be subjected to both marginal overloading and severe loading conditions.

Figure 1. Scientific framework for factor of safety (FOS) approach

Factor of frugality approach

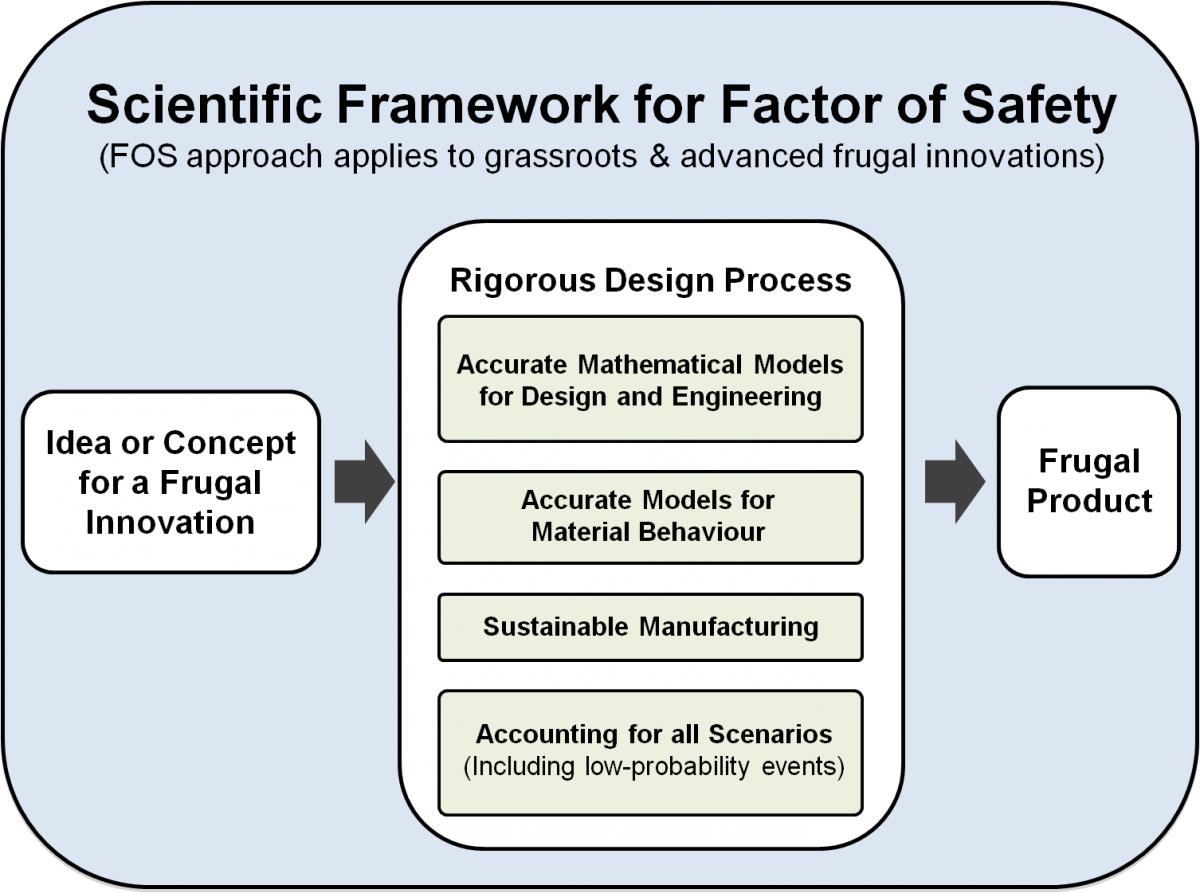

The new approach to frugal design was developed by coupling the existing FOS-based design (described earlier) with the new-found utilization of additional material saving schemes that are extraneous to the FOS approach. The vulnerability of frugal innovations notwithstanding, their lower FOS designs typically lead to streamlined products. Accordingly, rigorous design procedures accompanying low FOS designs – see Figure 1 – should be coupled with additional material-saving schemes for achieving the highest savings in material resources going into a frugal product. Accordingly, as seen in Figure 2, in a frugal design approach developed recently by Rao (2017b), the factor of frugality (F of FFOS) utilizes rigorous design procedures and additional material-saving schemes to conserve the maximum amounts of material resources going into a design thereby making it a frugal product. The symbolic representation shows both the classical FOS and the new factor of frugality (F), which is also dependent on the FOS value. In other words, the classical FOS is subsumed into the modern F value. The rigour of classical design with a low FOS ensures robust functionality of the frugal product under normal working and some overloading conditions with the attendant evasion of material padding. Additional material is saved for such a low FOS design by adopting extraneous schemes related to design, manufacturing and salvaging, to name a few.

Figure 2. Scientific framework for the proposed frugal design approach

Discussion

The advent and subsequent progress of frugal innovations from this century onwards is a force for good in the fight against global crises. In particular, climate change and resource scarcity, to name a few of the planetary crises, warrant judicious utilization of earth’s resources. Also, crises such as the one affecting global finance in 2007–2008 leave, in their wake, swelling ranks of unemployed in addition to those suffering from poverty. Consequently, widespread use of frugal products and frugal services, where possible, would aid in both uplifting the living standards of the society at large including the poor (Rao, 2014) and sustainable development.

Although many of the frugal products and frugal services developed to date could be utilized against the above backdrop, rigorous design seems to have been employed for only advanced frugal innovations used in sectors ranging from healthcare and transportation to defence. It should be noted that this work assumes the adoption of sound engineering principles in realizing advanced frugal products such as GE’s Mac 400, the Square Kilometre Array, the Tata Nano and others due to their sophisticated technology. In addition, technology titans such as GE and Tata also possess a highly skilled workforce, including scientists and engineers, who use their ingenuity for the scientific creation of these innovations. This is in contrast to grassroots innovations, which are typically fabricated by applying makeshift techniques. In any case, the need for a rigorous scientific approach, as presented here, applies to any frugal innovation, irrespective of whether it is a grassroots or advanced type, or anything in between.

The successful adoption of frugal innovations on a wider scale requires the realization of frugal products and frugal services, whose quality is not compromised for attaining lower costs. Although advanced frugal innovations have been created through rigorous application of science, a dedicated methodology for designing frugal products is needed from here onwards to systematically utilize science for creating frugal innovations from ground zero. In this regard, the factor of frugality developed recently by Rao (2017b) could be utilized to systematically build frugal products of any type from the design stage through to their successful realization by using suitable fabrication techniques. The factor of frugality is computed in two steps. First, a baseline design through the framework of Figure 1 is carried out for a low FOS. Second, additional material-saving schemes steeped in sustainability are employed whose savings are quantified. The FOS and the numbers from the second step are summed to give the factor of frugality (F of FFOS).

A FOS of, say, 1.5 is selected in the first step of utilizing the factor of frugality provided a rigorous design procedure is carried out for the concerned frugal innovation. The value of 1.5 is not arbitrary and has been taken from the aircraft industry where it is imperative to shell weight through rigorous design for eventually attaining efficient flight (Shanley, 1962; Norton, 2006). Besides, the value of 1.5 being just above the failure conditions would result in savings of raw materials as opposed to larger values. All the same, frugality comes with the caveat that even though lower costs can be achieved by changes to supply chain or sales and marketing, it is design-related parameters such as FFOS that can lead to the realization of frugal innovations for sustainable development with emphasis on human life. Therefore, rigorous design principles should be combined with the ingenuity of Jugaad to create myriads of good quality frugal products and also frugal services.

Although rigorous procedures accompanying a low FOS design of the first step would result in a streamlined product, additional savings for this low FOS product is possible through other schemes. These additional schemes comprising the second step of application of the factor of frugality are rooted in sustainability. Such schemes utilize various features of the design process such as manufacturing and salvaging from end-of-life systems to further economize material consumption for the low FOS design. An end-of-life system refers to any product that is nearing the end of its useful life, and such products may have valuable components that can be repurposed. For example, the fabrication of the low FOS design should employ suitable manufacturing technologies to reduce wastage of stock removed while also scouting for end-of-life systems that might already have such a manufactured part.

Overall, successful application of the factor of frugality approach results in a streamlined product with maximum material savings and hence generally maximal positive impact on the environment. The outlays involved in applying rigorous design procedures would inflate the costs of the frugal product in the short term with sales over the longer term aiding to go beyond the break-even point and eventually making a profit. Therefore, the decision to go frugal is a serious one that needs to be addressed during the conceptual or design stage so as to minimize the uncertainties in both the quality and margins of a frugal product. In other words, businesses and other entities have to take the rigour in design and engineering of these products as a must with room only for forecasting various scenarios of returns. However, costs could be lowered to some extent by the adoption of concepts such as open innovation systems, whose “open” environment allows unfettered flow of knowledge and also resources among the various stakeholders of an innovation ecosystem (Oganisjana, 2015).

Last but not least, companies, governmental bodies, academia, and other entities working with frugal innovations should actively develop research and development (R&D) programs to delve deeper into the scientific framework presented in this article for possible modifications and hence improving the functionality of frugal products in the foreseeable future. These R&D units should actively pursue the application of science, both pure and applied (engineering), to these innovations, whose contribution as low-cost alternatives for achieving better standards of living would be an indispensable tool for sustainable development. In particular, R&D activities on these innovations should develop on the scientific principles set in the framework presented in this effort by focusing on advanced studies in materials science, manufacturing processes, and design aspects, to name a few. These R&D programs are all the more important when human lives are at stake. Moreover, R&D entities pursuing frugal innovations should also team up with the poor in society to aid in the diffusion of these good quality products and also learn newer ways, if any, of utilizing frugality for the benefit of society (Rao, 2014). The makeshift nature of many of these innovations has to be nourished for their ingenuity and tempered with science to create robust frugal innovations for wide-ranging sustainable development.

Conclusions

This article highlights the importance of strengthening the foundations of frugal innovations through science and engineering. The dependence on sound scientific principles is warranted due to the makeshift nature of Jugaad, inherent in many of these innovations, which could make frugal products prone to failure working under normal or nominal conditions. Therefore, a scientific framework for the systematic realization of all types of frugal innovations has been presented in this article wherein classical tools of engineering design are brought to bear upon these innovations at the conceptual stage of the design process. This framework employing the recently developed factor of frugality is applicable to all types of frugal innovations irrespective of their degrees of sophistication in technology. Accordingly, the factor of frugality approach entails using traditional measures of design such as the factor of safety under tightly controlled conditions coupled with other schemes for saving extra materials to make frugal products robust. The weaving of pure and applied science around these innovations, created through the ingenuity of their resourceful creators, necessitates a strong R&D program, for delving deeper into the advanced aspects of these innovations, which would result in the systematic fabrication of frugal products that are sound in quality.

References

Basu, P. 2007. Science on a Shoestring: Microscopes Made from Bamboo Bring Biology into Focus. Nature Medicine, 13(10): 1128–1129.

http://doi.org/10.1038/nm1007-1128a

Downer, M., & Zgadzaj, R. 2014. Surf’s Up at SLAC. Nature, 515(7525): 40.

http://doi.org/10.1038/515040a

The Economic Times. 2010. Tata Motors Investigating Nano Fire Incident. The Economic Times, March 25, 2010. Accessed April 11, 2018:

https://economictimes.indiatimes.com/automobiles/tata-motors-investigati...

The Economist. 2010 First Break All the Rules: The Charms of Frugal Innovation. The Economist, April 15, 2010. Accessed April 11, 2018:

https://www.economist.com/node/15879359

The Economist. 2012. Rockets Galore: Cheap Smart Weapons. The Economist, September 29, 2012. Accessed April 11, 2018:

https://www.economist.com/node/21563702

The Economist. 2014. Low-Cost Airlines: Making Laker’s Dream Come True. The Economist, November 27, 2014. Accessed April 11, 2018:

https://www.economist.com/news/business/21635001-low-cost-airlines-have-...

The Economist. 2011. Tata’s Nano: Stuck in Low Gear. The Economist, August 20, 2011. Accessed April 11, 2018:

https://www.economist.com/node/21526374

Global NCAP. 2014. UN Crash Test Standards Would Make Cars Safer In India Says Global NCAP. Global New Car Assessment Programme (Global NCAP), November 3, 2014. Accessed April 11, 2018:

http://www.globalncap.org/un-crash-test-standards-would-make-cars-safer-...

Greenemeier, L. 2012. Four-Fingered Robot Can Replace Flashlight Batteries. Scientific American, August 19, 2012. Accessed April 11, 2018:

https://blogs.scientificamerican.com/observations/four-fingered-robot-ca...

Khanna, T., Kasturi Rangan, V., & Manocaran, M. 2005. Narayana Hrudayalaya Heart Hospital: Cardiac Care for the Poor. Harvard Business School Case N9-505-078. Boston, MA: Harvard Business School.

Nordling, L. 2012. Recycled Dishes Form Telescope Network. Nature, 488(7413): 571.

http://doi.org/10.1038/488571a

Nordling, L. 2013. Can the Southern African Large Telescope Live Up to Its Potential? Nature, 502(7473): 608–610.

http://doi.org/10.1038/502608a

Nagral, S. 2014. The Chhattisgarh Tragedy and Indian Surgeons’ Love for Speed. Rediff.com, November 28, 2014. Accessed April 11, 2018:

http://www.rediff.com/news/column/the-chhattisgarh-tragedy-and-indian-su...

Norton, R. L. 2006. Machine Design: An Integrated Approach. New Jersey: Pearson Prentice Hall.

Oganisjana, K. 2015. Promotion of University Students’ Collaborative Skills in Open Innovation Environment. Journal of Open Innovation: Technology, Market and Complexity, 1(1): 18.

https://doi.org/10.1186/s40852-015-0021-9

Rao, B. C. 2013. How Disruptive Is Frugal? Technology in Society, 35(1): 65–73.

https://doi.org/10.1016/j.techsoc.2013.03.003

Rao, B. C. 2014. Alleviating Poverty in the Twenty-First Century Through Frugal Innovations. Challenge, 57(3): 40–59.

https://doi.org/10.2753/0577-5132570302

Rao, B. C. 2017a. Advances in Science and Technology Through Frugality. IEEE Engineering Management Review, 45(1): 32–38.

https://doi.org/10.1109/EMR.2017.2667219

Rao, B. C. 2017b. Revisiting Classical Design in Engineering from a Perspective of Frugality. Heliyon, 3(5): e00299.

https://doi.org/10.1016/j.heliyon.2017.e00299

Raturi, P. 2010. Potter Power: Son of the Soil. Entrepreneur, December 2010: 108–109.

Shanley, F. R. 1962. Historical Note on the 1.5 Factor of Safety for Aircraft Structures. Journal of the Aerospace Sciences, 29(2): 243–244.

https://doi.org/10.2514/8.9385

Shigley, J. E., & Mischke, C. R. 1989 Mechanical Engineering Design. New York: McGraw Hill, Inc.

Urugal, A. C. 2015. Mechanical Design of Machine Components. New York: CRC Press.

Keywords: factor of frugality, factor of safety, frugal innovation, research, sustainable development